|

The third era vacuum convey or uses multi-stage ejector pump and metal filter. Our products are the third era products. We develop

the vacuum conveyor follow the combination of the aerospace and international GMP criterion strictly. Our technology has achieved international advance level. Our products can solve the stratification of powder and granules, and eliminate the static electricity.

characteristic:

---Using compressed air as primary energy sources

---According with GMP standard

---Solving the stratification of powder and granules

---The filters made of Ti will never be jammed and be abraded

---Eliminate the static electricity

---Made of nontoxic and corrosion resistant materials

---Leakage free capsule, to prevent cross contamination

---Materials are not adhering to the inner surface of the conveyor

---Intelligent control and high automation

---Modular structure, easy to clean and dismantle

---Small and light ,easy to install

---Low noise and free from vibration

---Energy saving and low running cost.

QVC conveying system consist of material container, pipeline, vacuum conveyor, control system and so on. The max distance to convey is 30m in height or 90m in length and the max conveying capability can reach 18 t/h.

Model and parameter:

Types

|

transportation ability (kg/h) |

air pressure

(Mpa) |

air consume

(l/min) |

over size

(mm) |

QVC-1 |

350 |

0.4-0.6 |

180 |

dia.140*560 |

QVC-2 |

700 |

0.4-0.6 |

360 |

dia.213*720 |

QVC-3 |

1500 |

0.4-0.6 |

720 |

dia.290*850 |

QVC-4 |

3000 |

0.4-0.6 |

1440 |

dia.420*1150 |

QVC-5 |

6000 |

0.4-0.6 |

2880 |

dia.420*1150 |

Conveying model:

Pneumatic conveying systems are divided into four categories: positive pressure system, vacuum conveying system, upgrading system and fluidised beds.

Conveying system |

Advantages |

Disadvantages |

cost |

equipment cost |

running cost |

Positive pressure |

High capacities Long distance conveying |

Risks of leakage Heavy installations Expensive components Wear on material and system |

High |

High |

Vacuum conveying system |

No leakage of material Simple to install

Dustless

Easy to control |

Limited conveying distance

Limited capacity

Usually intermittent operation |

Low |

Low |

Upgrading system |

No leakage of material |

Hard to control

Equipment complex

Big

Short distance to convey |

High |

Common |

Fluidised beds |

Angle of conveying from only 2–3° slope

No moving parts |

Dusty conveying

Open system |

High |

High |

VACUUM CONVEYING:

The first era vacuum conveyor was birthed in Europe in 70s.Because the technology is poor then, the products is large and low efficency. In the early 80s,the industrial dust collector is used as vacuum source of conveyor in China. The second era vacuum conveyor uses industrial blow-suck pump and fibr-filter. The third era vacuum convey or uses multi-stage ejector pump and metal filter.

THE PROBLEM OF VACUUM CONVEYING:

The stratification of powder and granules

Eliminating the static electricity

Running automatically

THE ADVANTAGES OF VACUUM CONVEYING:

Suit for granules and powder;

Low noise level;

Leakage free capsule, to prevent cross contamination;

Low energy consumption and high efficiency ;

The max distance to convey is 30m in height or 90m in length.

Easy to install.

We test your powders:

In our test facility different conveying distances and materials are tested in order to simulate your requirements and applications. The test results are available at your distributor. You can rest assured to get the optimum dimensioning of your installation, as well as the proper accessories and control system.

EXAMPLE OF MATERIALS THAT HAVE BEEN TESTED BY US:

Aerosil |

Coffee |

Dextrose |

Dicalite |

Rice |

Acetylsalicylic acid |

Caustic soda |

Fat substance powder |

Milk powder |

Sugar, granulated |

Aluminium oxide |

Detergents |

Filter material |

Nib sugar |

Tea |

Aluminium stearate |

Colour powder |

Fish food pellets |

Nuts |

Wheat flour |

Baron acid |

Nickel powder |

Gelatin powder |

Peas |

Plastic granules |

Brewer’s yeast |

Coffee beans |

Gun powder |

Potato flour |

Sprinkles |

Calcium cloride |

Fish food |

Iron oxide |

PVC powder |

Rubber granules |

Calcium stearate |

Cocoa powder |

Magnesium oxide |

Potato starch |

Soya flour |

Calcium nitrate |

Cocoa beans |

Malt |

Resin powder |

Wall paper glue |

Carbon, active |

Citric acid |

Maize flour |

Salt |

Titanium dioxide, TiO2 |

Carrots, dried |

Cellulose powder |

Manganese dioxide |

Sugar caster |

Mustard seeds |

Cases:

We will provide the high quality products and good service according to what our clients need, by which you can make sure there is no leakage of material and no explosion risk. Examples of how to choose a conveyor are given

1.Capsule:

2.Tablet Press:

3.Mixer:

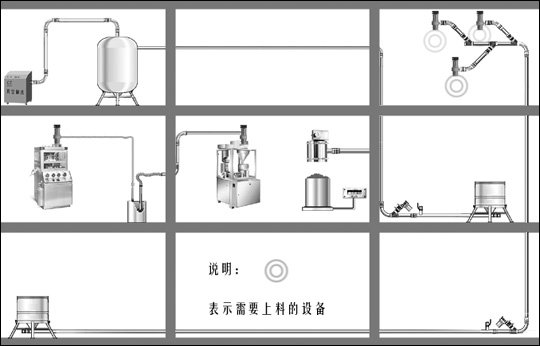

4.Vacuum conveying system:

With vacuum systems, material can be sucked from several pick-up points and collected at one receiving point. This is the opposite of what happens in positive-pressure systems. The system has a lot of advantage, such as, No leakage of material, simple to install,

dustless, easy to control and so on. The pollution for entironment of the system can reach to zero. And the system follow the GMP standard.

|